What are the differences between the technologies? And what are the benefits of each?

When most American consumers think of recycling, they probably think of the mechanical variety, in which plastic is sorted by type of plastic (number 1, 2, 3, etc.). Then it is shredded or melted and used to manufacture new products like decking, furniture, or plastic bottles. To date, mechanical recycling has only been able to affordably handle between 10% and 20% of plastic waste. But a new group of technologies, advanced recycling technologies, have grown in popularity and are opening up a whole new world of possibilities for circular manufacturing from the remaining post-use plastics that are presently destined for a landfill. Advanced recycling includes a suite of different processes, including pyrolysis (which is similar to Brightmark’s proprietary Plastics Renewal™ technology), gasification, and solvolysis, which return post-use plastics to their original chemical composition so that the materials can be remade into something new.

Whatever your recycling persuasion, it’s unmistakable that plastics recycling is a critical tool in humanity’s toolkit for tackling the deluge of plastic waste humanity faces. But how are these technologies different? And what are the benefits of each? Let’s take a look.

Round 1: Flexibility and applicability

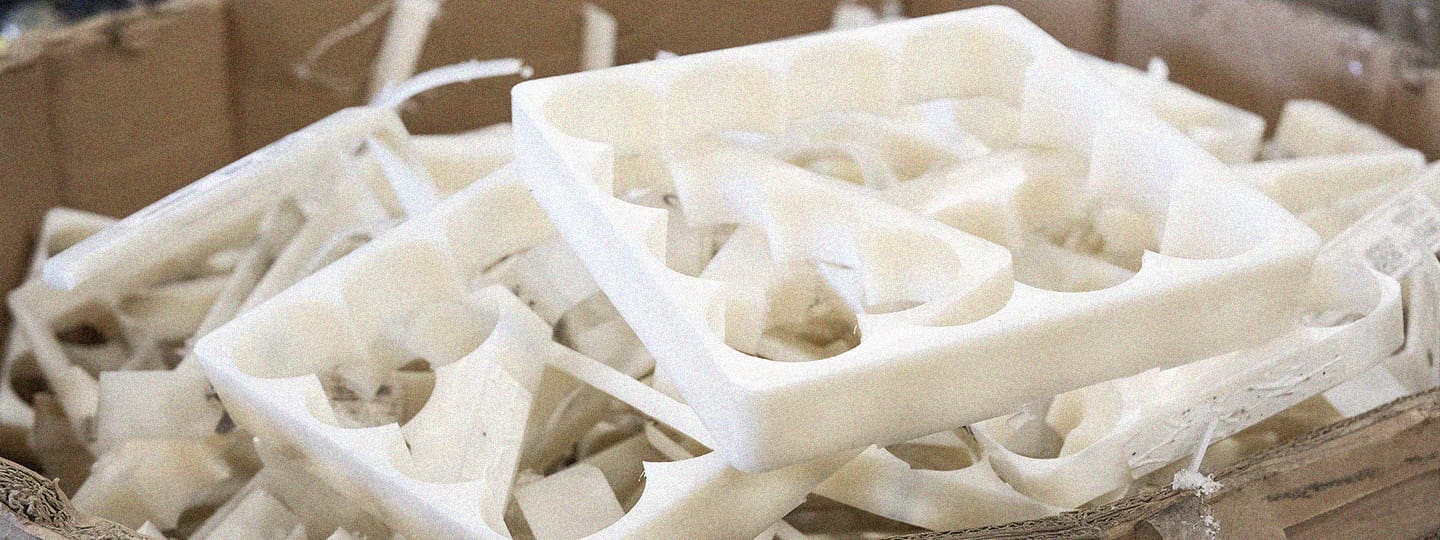

The plastics you set out in your curbside bin are sent to a mechanical recycling facility for processing, where types 1 (PET), 2 (HDPE), and 5 (PP) are sorted for the reprocessing market. Sometimes type 6 (PS) is also recycled in this manner, but many localities don’t ship these materials out for recycling, and they end up being landfilled or incinerated. Most consumers don’t know that, despite tossing all of their plastic packaging into the recycling bin with the best intentions. Many of these materials are never processed because mechanical recycling can’t recycle them affordably.

Advanced recycling, on the other hand, can often accept plastics 1 through 7 for processing. In many cases, it frees up other materials destined to go to the landfill that can be recycled mechanically. (Think metals, cardboard, and glass that become commingled with previously unrecyclable plastics).

Round 2: Greenhouse gas emissions

Significant research has been conducted separately into the climate impacts of mechanical and advanced recycling methods—comparing each technology to incineration. Few studies have compared mechanical and advanced recycling technologies head-to-head on carbon emissions. Still, the research that is available suggests that mechanical recycling produces fewer greenhouse gas emissions than advanced recycling because it is less energy intensive.

However, this includes a significant caveat–these emissions are highly dependent on the energy source used to power a given recycling facility. Both mechanical and advanced recycling are needed to address the overall plastic waste issue.

Round 3: Dirty recyclables

It’s happened to everyone. You approach the trash and recycling bins at your local farm-to-table salad joint and freeze at the decision point—do you recycle the salad bowl lid or trash it?

If you choose to recycle, you’ll be disappointed to learn that mechanical recycling facilities typically cannot accept “contaminated” plastics like unwashed, post-use packaging. So unless you’re taking your salad lids home for a rinse before tossing them in the blue bin, chances are they’re ending up in a landfill or incinerator.

But do not fret—advanced recycling solves this challenge and can accept a set percentage of contaminated plastics based on weight. The impact of this differentiator is tremendous, enabling advanced recycling to tackle waste streams that previously had no circular solution.

Round 4: Innovation

Plastic production began to spike in the mid-20th century, and the first recycling mill to accept household plastic recyclables opened in 1972 in Pennsylvania. By the 1990s, curbside recycling collection had expanded to much of the United States, with those plastics headed to a rapidly expanding network of mechanical recycling centers. Over the next 30 years, the use of mechanically recycled plastic expanded as the demand for those materials increased. Modern mechanical recycling creates the building blocks for recycled products made from plastic waste, including shoes, toothbrushes, and furniture.

However, the application of mechanical recycling can only go so far. With this process, plastic declines in value and strength each time it is processed. So while a given product could typically be recycled once using mechanical methods, it’s increasingly difficult to close the loop again and keep those materials active in the circular economy. Without restoring plastics to their original chemical building blocks, much of the plastic recycled mechanically today is “downcycled,” during which plastic products are refabricated to produce products of lesser quality.

Advanced recycling works differently. It can renew plastic waste to its original chemical form, which can be used to manufacture brand-new plastic products of a similar quality as the original. With this type of recycling, the chemical compounds can remain in circulation in the economy and are likely to be recycled more than once. The manufacturing capabilities of chemical recycling are vast–using plastic feedstock (raw materials), many products can be manufactured that look, feel, and perform identically to those products by virgin plastic feedstocks.

Round 5: Consumer access

Since mechanical plastic recycling has been around since the 1970s, it is no surprise that this technology has a foothold with the American public. Curbside recycling collection expanded from 1,000 cities in 1988 to 5,000 localities by 1992. Rising public awareness about environmental challenges like the hole in the ozone layer and global warming left people reaching for simple actions they could take to better care for the planet. Today, most U.S. localities have offtake arrangements with mechanical recyclers to purchase the easiest-to-recycle plastics from curbside bin collections, and 59% of Americans have access to curbside recycling pickups.

While advanced recycling could be seen as a burgeoning industry, it’s been around for decades. However, it’s just now gaining popularity worldwide. Most of the plastics recycled via this process are set up with industrial offtake agreements, not from curbside recycling. This means that in many cases, plastic waste is purchased as a raw material for the advanced manufacturing process and is not directly tied to curbside recycling. But, the existing recycling infrastructure is changing to try and accept the significant increase in sorted materials and divert to the proper recycling technologies.

Round 6: Public preference

Today, at least 94% of the American population has access to some kind of recycling infrastructure, whether a curbside collection program or local drop-off centers. However, the extent to which consumers understand what happens to their recyclables once they’re picked up and by which process they are recycled is unclear.

Data suggests that, frankly, consumers just don’t care. Mechanical vs. advanced recycling—it’s all positive to them as long as materials see circular uses. Indeed, recent polling data reveals that 90% of Americans care more about whether a plastic item avoids ending up in the trash or littering the environment over which process is used to recycle the item. Furthermore, 65% of survey participants strongly supported advanced recycling, compared to 58% strongly supporting mechanical recycling.

Ultimately, mechanical and advanced plastic recycling technologies have clear, unique benefits and play an essential role in the waste hierarchy.

With broad public support, now is the moment for recycling technologies to come of age and play a more significant role in the circular economy, but there’s still much progress to be made. For example, 98% of plastic packaging is still made from virgin feedstock. But change is on the horizon, thanks partly to consumer preferences: global demand for recycled plastic grew by 17% between 2012 and 2016. It’s vital that the U.S. pursue a combined expansion of both advanced and mechanical recycling if humanity is to close the loop on plastic waste once and for all.