The strategic partnership continues to leverage Brightmark’s innovative Plastics Renewal® technology to transform difficult-to-recycle mixed plastics from medical implants into the building blocks for new, circular plastics

WARSAW, Ind. — Brightmark LLC, a circular innovations company with a mission to Reimagine Waste®, announced today that its strategic partnership with Lewis Salvage, an independently-owned recycling company based in Warsaw, Indiana, a location with the world’s highest concentration of orthopedic design and manufacturing companies, has surpassed one million pounds of plastics recycled, successfully diverting medical plastic waste away from landfills and incinerators.

“Surpassing the 1-million-pound mark is more than just a number; it’s proof that advanced recycling technologies can make a real impact on the healthcare industry’s plastic waste challenge,” said Bob Powell, Founder and CEO of Brightmark. “Our proprietary Plastics Renewal® technology is at the core of this success, enabling us to recycle a broad range of plastics—including those from healthcare settings that would otherwise be discarded. Since launching this effort, we’ve increased the volume of plastics recycled and demonstrated a model for the recycling of medical plastics.”

The use of single-use medical plastics continues to grow, fueled by rising demand for sterile, disposable devices and packaging in healthcare settings. Plastic makes up about 25% of the 14,000 tons of waste generated daily in US health care facilities every day. And 91% of plastics, including those used in health care, are not recycled and either reside in landfills or the environment.

This achievement marks a significant step forward in addressing the growing environmental challenge posed by single-use plastics utilized in the healthcare industry. Since the inception of this strategic partnership on July 30, 2024, Brightmark has increased its recycling efforts from an initial 400,000 pounds of plastic waste to over 1 million pounds.

“Our partnership with Brightmark is transforming waste into valuable materials, reducing landfill use, and creating new opportunities for businesses to join the circular economy,” said Cary Lewis, Owner & CEO of Lewis Salvage. “As Warsaw’s orthopedic manufacturing industry grows, manufacturers are seeking more sustainable, efficient recycling solutions. Together, we’re proving that innovative technology and commitment can drive true environmental stewardship.”

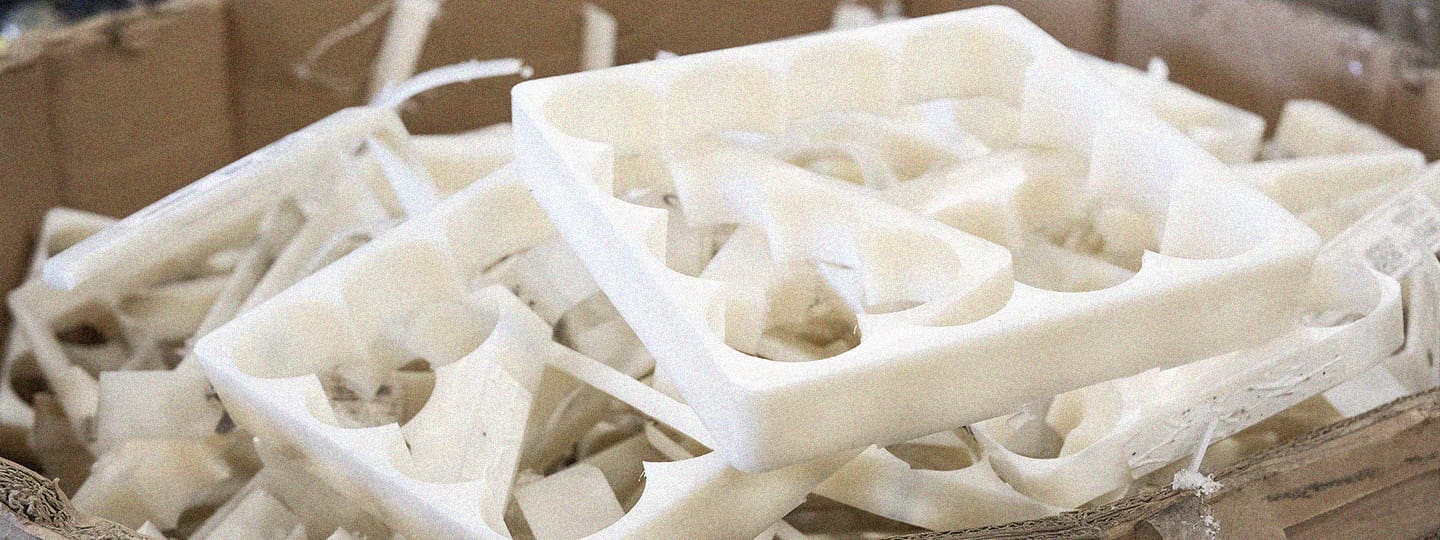

Through Lewis Salvage’s Minimized Landfill Recycling Program, healthcare plastics from medical device and orthopedic implant manufacturers are collected and transported to the Brightmark Circularity Center in Ashley, Indiana. Using Plastics Renewal® technology, Brightmark transforms a wide range of difficult-to-recycle materials—including trays, films, Styrofoam, packaging, and ultra-high molecular weight polyethylene (UHMW PE) machining chips and turnings from implant manufacturing—into the building blocks used to create new, circular products. Materials that were once considered unrecyclable are now being converted into valuable products.

This milestone builds on last year’s launch of the Brightmark and Lewis Salvage partnership, which set out to improve healthcare plastics recyclability in the Warsaw region. Since then, the collaboration has expanded its impact, diverting even more difficult-to-recycle medical plastics from landfills and transforming them into valuable circular products.