Mechanical recycling is the recycling we have become most familiar with. It’s the type of recycling we expect when we push our plastics to the curb in those typical bins. When those plastics are sent to a recycling facility, they are transformed into raw materials or new products without significantly changing the material’s chemical structure. For example, when plastic bottles are mechanically recycled, they are turned into other plastic bottles. Most of the time, this can be done without affecting the quality of the new product.

Mechanical recycling was seen as a breakthrough as the green movements of the 1970s ramped up household recycling. It was the familiar person’s way of feeling like they were doing something helpful for the planet. And while it did contribute to reducing waste, the buildup of unrecyclable plastic proved too much to overcome, leaving governments in a lurch when it came to finding a home for hard-to-recycle plastic.

Ban On Plastics Imports

While you may think your plastic continues to be whisked away to factories for recycling, the reality is different: for decades, it has been shipped to poorer countries where workers are paid to sort through your recyclables. In 2018, the equivalent of 68,000 shipping containers full of plastic waste was exported from the United States to other countries, with China being chief among them.

But at the beginning of 2018, China stopped accepting imported plastic. This affected the global recycling trade as China had been the world’s largest waste and hard-to-recycle plastics importer. With nowhere for this plastic waste to go, it became a virtual “hot potato” of waste as countries tried to figure out where it would end up.

Global Recycling Trade Challenges

Even though fewer countries accept our recycling, Americans are consuming more and more, which means the amount of waste produced in this country is not leveling off. And as recycling facilities and countries continue to boost the price to take in recycling, it is no longer an attractive option. Our recycling has nowhere to go.

Plastics Recycling Innovation at Brightmark

The world has been yearning for a solution to our hard-to-recycle plastics. It has been a stop-start process, as nothing has caught on to help us make a real difference.

But a breakthrough in recycling technology —advanced plastic recycling or plastics renewal —could be the solution, and Brightmark is pioneering this technology.

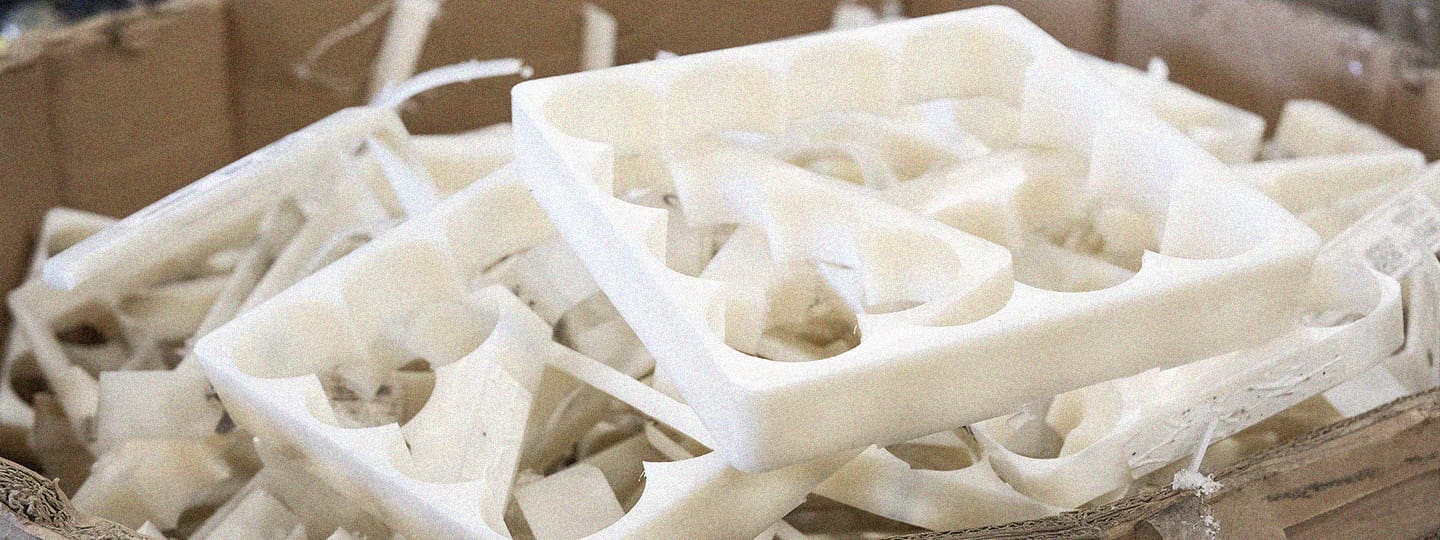

Advanced recycling can accept all types of plastic and transform these raw materials into new products, including fuel, wax, and other plastics. Advanced plastic recycling has vastly expanded the market for used plastics and is making it easier for us to Reimagine Waste and respect Earth’s natural resources.

At Brightmark, our plastics renewal process works by collecting plastic waste and converting it into pellets which are then heated and vaporized in an oxygen-starved environment. These vapors are captured, cooled, and processed by-products like diesel fuel and candle wax.

The result is less plastic waste going into landfills and the environment and more materials that can be used repeatedly. It’s a win for humanity and those who wish to make a cleaner, safer planet.

Additional Resources

- The Recycling Partnership website: https://recyclingpartnership.org/

- Environmental Protection Agency: https://www.epa.gov/recycle

- Keep America Beautiful: https://kab.org/goals/improve-recycling/