Certification ensures compliance with high ecological and social sustainability requirements, greenhouse gas emissions savings, and traceability throughout the supply chain

Ashley, IN, December 09, 2021: Brightmark, LLC the global waste solutions provider, today announced that its Ashley, Indiana Plastics Renewal Facility has been ISCC PLUS (International Sustainability and Carbon Certification) certified. The certification is provided by SCS Global Services, a pioneer and leader in the field of sustainability standards and third-party certification, working across the economy in the natural resources, built environment, food and agriculture, consumer products, and climate sectors.

ISCC PLUS certifications are conducted by independent third-party Certification Bodies cooperating with ISCC. Competent and trained auditors, evaluating compliance with the ISCC sustainability standard, conduct the audits. ISCC certification ensures that biomass is not produced on land with high biodiversity and high carbon stock, good agricultural practices protecting soil, water, and air are applied, human rights, labor, and land rights are respected, sustainable material is traceable throughout international supply chains and that greenhouse gas reduction targets are met.

“Brightmark is proud to receive ISCC PLUS certification for our flagship Ashley, Indiana plastics renewal facility,” said Bob Powell, Founder and Chief Executive Officer of Brightmark. “SCS Global Services has worked hard for decades to recognize companies striving to advance sustainability, and this certification serves as an additional proof point of Brightmark’s commitment to Reimagining Waste while ensuring environmental responsibility throughout our operations.”

SCS Global Services has established programs and services designed to recognize the outstanding achievements of companies, institutions, and organizations who are meeting the highest levels of performance in environmental protection, social/ethical responsibility, product safety, and quality, and stimulate continuous improvement on the path toward sustainability. In this undertaking, they employ a life-cycle framework, state-of-the-art science, proven analytical methods, performance metrics, and professional expertise.

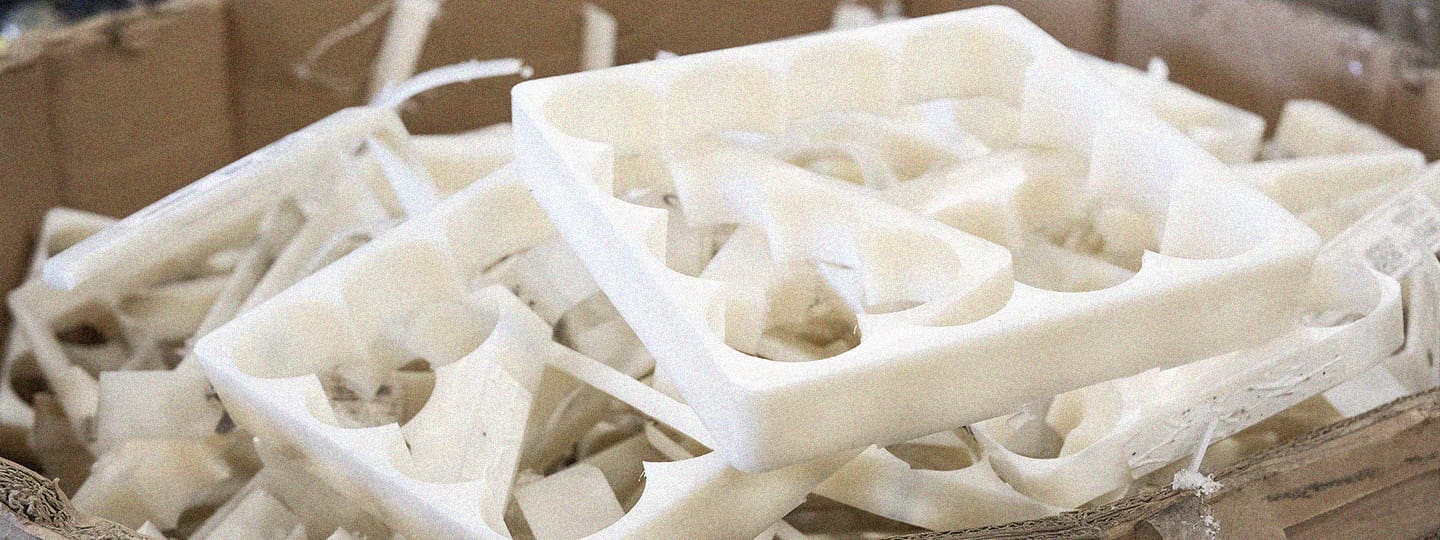

When fully operational, Brightmark’s Ashley plastics renewal facility, now in pilot phase, will divert 100,000 tons of plastic waste each year from landfills and incinerators and convert it into 18 million gallons of ultra-low sulfur diesel fuel and naphtha blend stocks and 6 million gallons of wax – this is more plastic than the weight of 5,400 tractor-trailers or seven Brooklyn Bridges. Through a breakthrough proprietary process, Brightmark has the unique ability to recycle all types of plastic (1-7) – including the difficult to recycle plastic types 3-7 which cannot readily be recycled, like plastic film, styrofoam, flexible packing, car parts, toothbrushes, and children’s toys – directly into useful materials. The Ashley facility is anticipated to achieve fully operational status in 2022. Brightmark utilizes the technology of its subsidiary company Res Polyflow, LLC in the plastics conversion process.